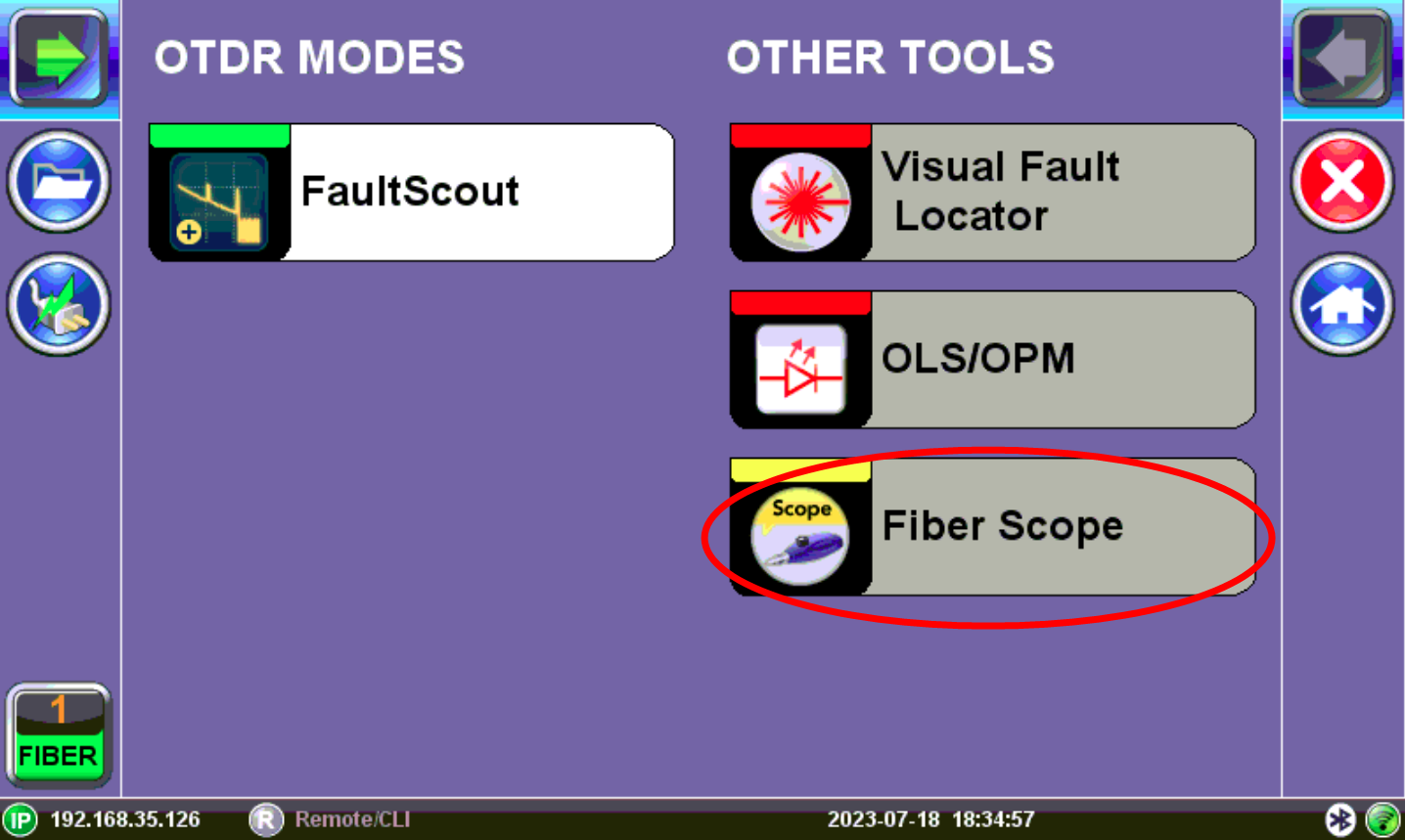

Fiber Scope

The VeEX digital fiber inspection scopes evaluate fiber optic connectors for dirt and end face quality. The handheld probe design enables easy inspection of patch cords and connector panels. Extended tips are available for hard to reach bulkhead or patch panel connectors. Clear images are displayed on the test sets for immediate analysis and can be saved for record keeping.

The Fiberscope test application can be used in conjunction with any VeEX Digital Fiber Inspection Microscope.

All DI series fiberscopes can auto freeze image when focus is achieved to capture the image and qualify the connector endface for cleanliness and damage per IEC 61300-3-35. For more information about available connector tips, see the DI-1000/DI-1000MPO/DI-3000 Digital Fiber Inspection Microscope Adapter Tips Guide.

All wired fiber inspection scopes are powered via a USB Type-A connection with a host device or the VeEX Power Bank/WiFi Bridge. For host devices that have Micro-B or Micro-C input ports, USB Type A to Micro-B or Micro-C OTG dongle adapters are available as an add-on order from VeEX.

The VS-500 is no longer offered but is still supported by VeEX test sets.

The Importance of Fiber Connector Inspection

Dirty or scratched connectors introduce loss, increase ORL and/or damage other connectors (Loss and Return Loss becomes more critical at higher data rates). End-face contamination is a leading cause of fiber link failures in data centers, corporate networks, MSOs and Telecom environments.

Fiber Inspection Scopes provide a magnified image of the fiber optic connector’s end face, focusing on the contact areas (most likely to impact network performance or permanent damage by mating of contaminated connectors). Images, visual inspection, and automated tools are often used to grade the health and cleanliness of connectors, after polishing or cleaning and before being used.

To achieve maximum power and prevent false readings, clean the optical fiber connector interfaces before inserting them into the test port.

For more information on Best Practices, see Test Fiber and Initial Preparation.

|

|