Test Fiber and Initial Preparation

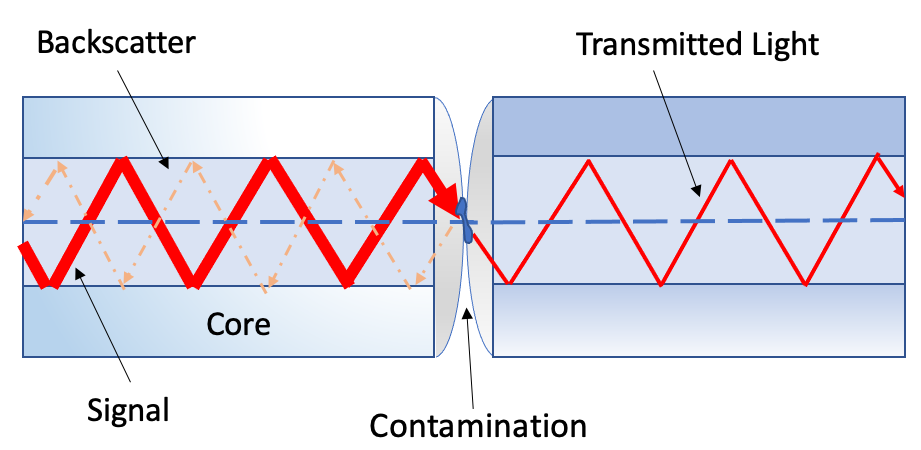

Dirt, dust, and other contaminants severely impact high-speed data transmission in optical fibers and dirty connector end-faces are often the number one cause of link failures. High insertion loss and/or high back reflection can result in transmission loss or high bit errors and poor BER.

Most measurement variations and test repeatability conditions in fiber-optic systems can be traced back to the cleanliness of optical connections. Contamination of fiber end faces not only affects optical power levels but also impacts back reflectance performance and levels which is harmful to sensitive optical components.

Dirty fiber end faces can cause back reflectance and insertion loss

Contamination

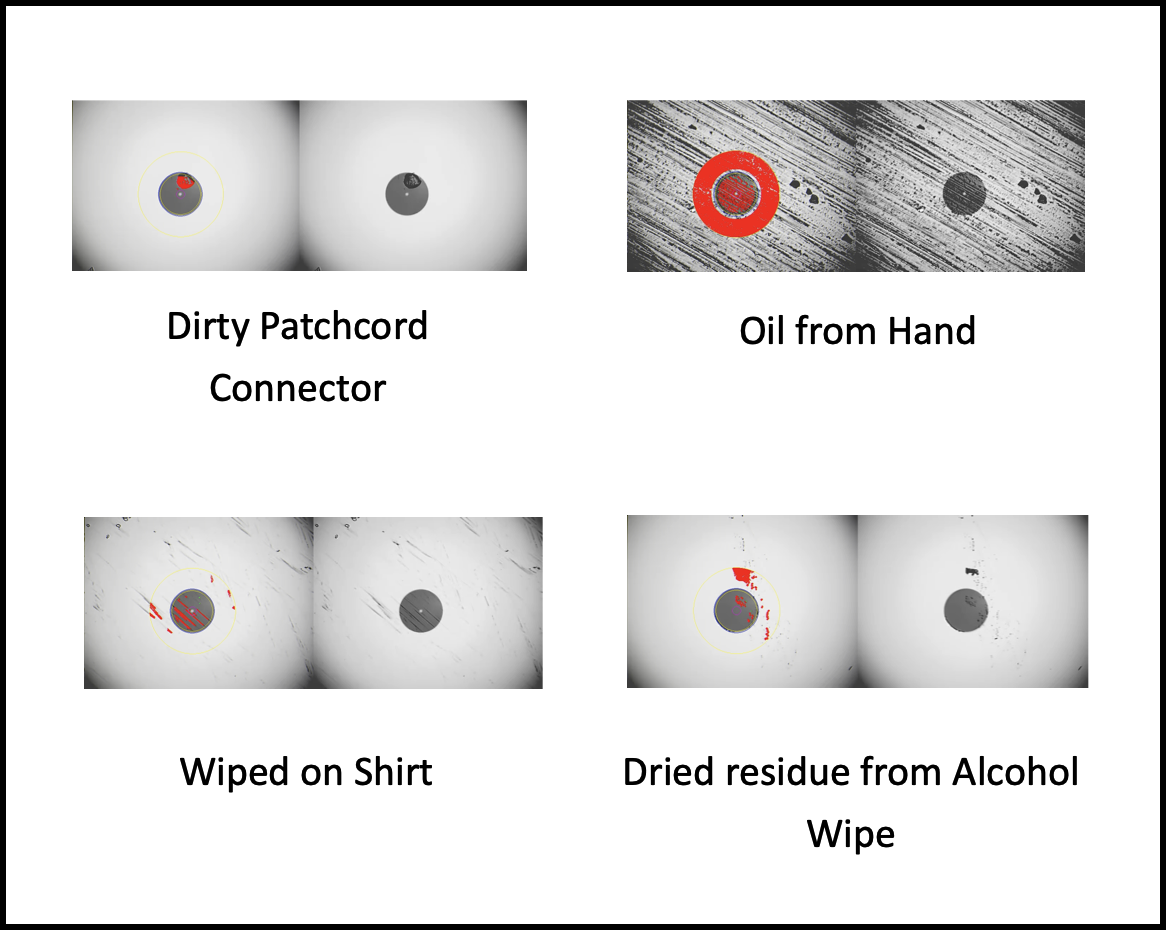

Optical connectors are susceptible to contamination from air borne particles and human body oils when exposed. Left over liquid residue from improper cleaning can also leave the fiber end face contaminated. The smaller the fiber core, the more severe the problem is likely to be, especially when considering that fiber core diameters can range from 62.5 microns all the way down to 8 microns in size.

Types of contamination viewed from a Fiber microscope

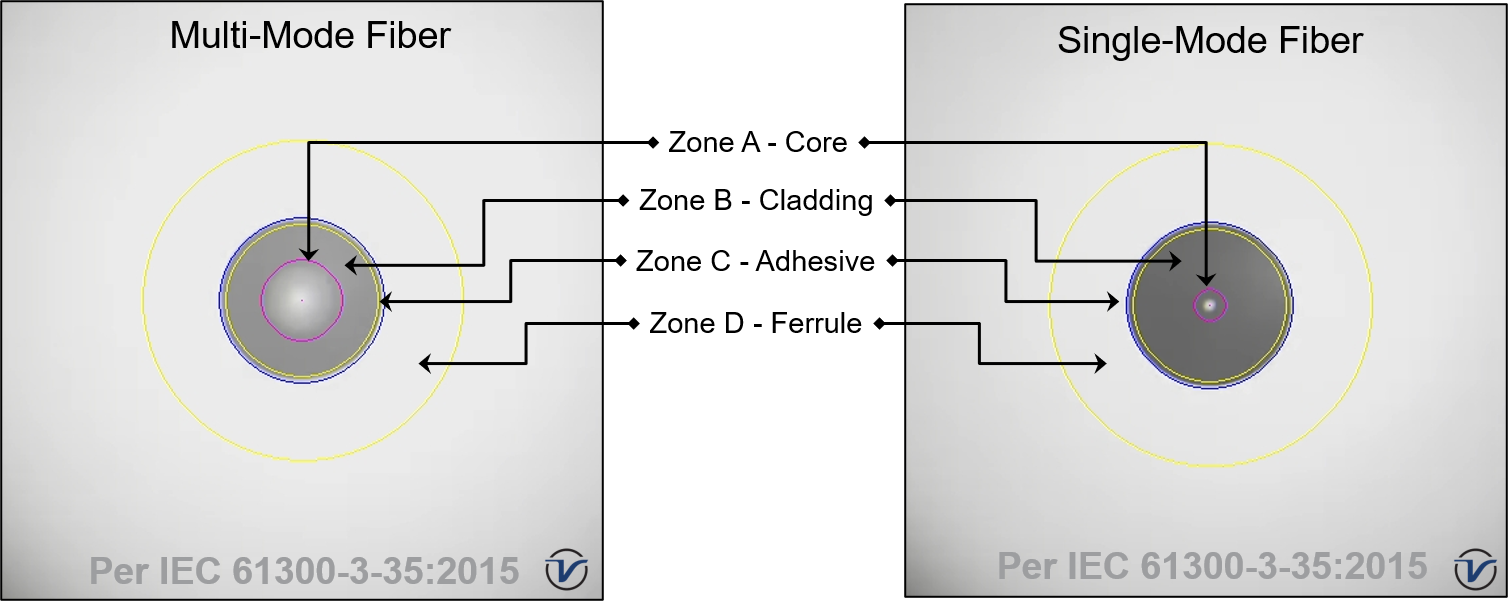

Cross-section-mode and multi-mode fiber zones

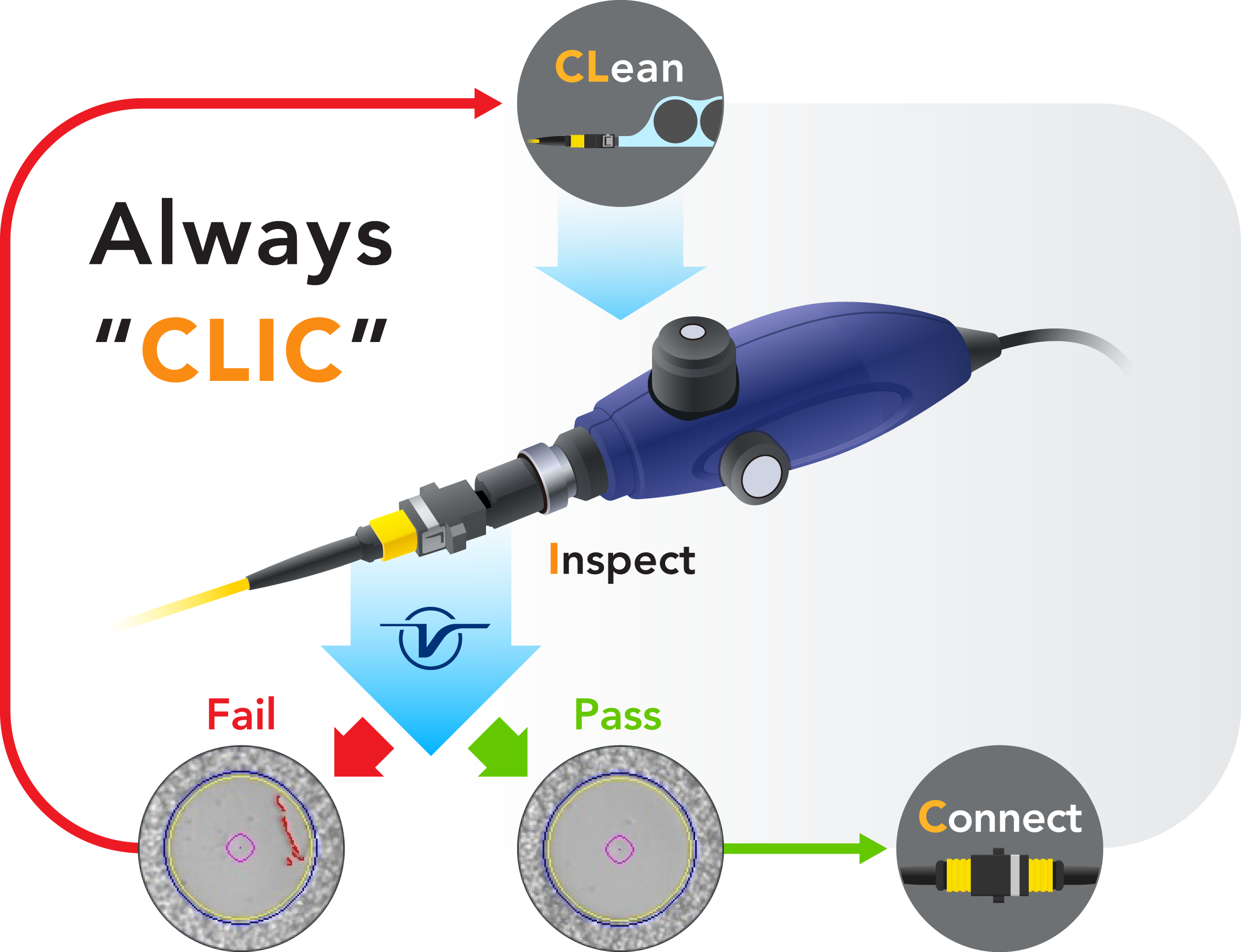

Inspection

Whenever possible, inspect the fiber-optic connection (connectors, bulkheads, and test interfaces) with a fiber microscope. It is recommended to wear laser safety glasses when working with fiber-optic connections. Always check that the laser or transmitter is disconnected before cleaning the connector end faces.

Cleaning Procedure

To ensure proper and effective cleaning of optical fiber connectors and interfaces, use the following cleaning materials:

- Isopropyl alcohol

- Lint free soft tissues

- Ferrule cleaners (1.25mm and 2.5mm versions)

- Connector reel cleaners (CleTop or similar)

Optical fiber cleaning materials clockwise from left--isopropyl alcohol, lint free soft tissues, connector reel cleaners, and a ferrule cleaner

Clean the connector end-face by rubbing it onto a lint-free wipe dampened with isopropyl alcohol

Procedure

- Dab the contaminated connector end-face with a wipe that has been dampened with isopropyl alcohol - the solvent will dissolve and remove contaminants that have dried and attached to the connector or fiber end-face.

- Rub the fiber end-face perpendicularly against a dry lint free wipe several times.

- Alternatively, use compressed air to dry the surface quickly. Do not blow or allow the connector end face to air dry as this may leave a residue behind which is often more difficult to clean and which can attract even more dirt.

- Re-inspect the fiber end-face with an optical microscope to check that all the contaminants have been removed properly - if not, repeat the process.

![]() Using Compressed Air

Using Compressed Air

In some clean air situations, filtered air is acceptable for use, which is free of oil and moisture to remove debris and clean a fiber optic connection. However, unless very strict cleaning procedures are followed, air-driven contaminants can cause more problems.

To use compressed air, hold the can upright. If the can is held at a slant, propellant could escape and dirty the optical device. First spray into the air, as the initial stream of compressed air could contain some condensation or propellant. Such condensation leaves behind a filmy deposit.

Best Practices

- Never touch the end face of an optical fiber connector with any hands or fingers.

- Always install dust caps on unplugged fiber connectors.

- Store unused dust caps in a resealable plastic bag to prevent dust accumulating.

- Never re-use optic cleaning swabs or lint free wipes. Always discard materials that have been used.

- Ensure all alcohol or solvent residues are removed after using wet cleaning techniques

- It is recommended to re-inspect the bulkhead receptacles and connector end face using a fiber microscope following the cleaning and prior to use.

Best practices for inspection and cleaning prior to connecting an optical fiber